Laser and plasma cutting are well-suited to CNC machining production processes. These technologies are thermal processes commonly used in industrial settings to cut materials. The main difference between the two technologies lies in the source of the technology’s cutting power: laser cutting machines use a narrow and intense ray of light to cut through materials, whereas plasma cutters use a device for generating a directed flow of plasma for cutting.

What is laser cutting and how does it work?

Laser cutting works by directing the highly concentrated energy of a laser beam directed onto a material, producing local melting and separation of the workpiece. Depending on the details of the cutting technique, the laser may melt the material, with an assistive gas stream blowing the melted material out of the way. Or it may directly change the cut material from solid form to gas (sublimation), with the kerf removed in vapor form. Laser cutting equipment can cut structural and pipe materials as well as thin sheets.Three main types of lasers are used for laser cutting: CO2, neodymium, and fiber laser systems. Although the laser cutter types are all similarly constructed, they differ in that each kind of laser has a different power range, and each is best suited to certain material types and thicknesses.Laser cutting is widely used in sectors like electronics, medicine, aircraft, and transportation. Due to the laser’s ability to create precise cuts and finishes, it is mostly used to cut metals like tungsten, steel, aluminum, brass, or nickel. Lasers are also used to cut wood, silicon, ceramics, and other non-metals.

Laser cutting advantages vs. plasma cutting

- Accuracy: The energy of a laser beam is concentrated on a single tiny area, penetrating the material and cutting it. This process produces a thin cutting seam (kerf) in the workpiece, as opposed to the wider kerf produced by plasma cutting. The thinner cut made by a laser makes it useful for complex, delicate cutting tasks that cannot be accomplished by a plasma cutter.

- Wide Range of Materials:Laser cutters are capable of cutting a wide range of materials, including: metal, wood, plastics, and ceramics. Plasma cutters, on the other hand, are limited to cutting conductive materials.

- Speed: Laser cutters are a more energy-efficient and faster option for cutting metal compared to plasma cutters, making them a better choice for the environment.

What is plasma cutting and how does it work?

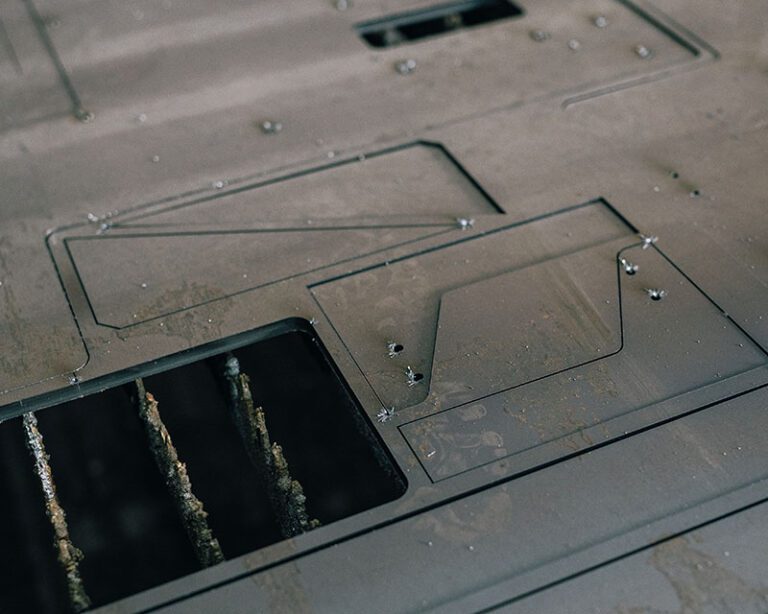

Plasma cutting is a cutting technology that works by forcing a hot, electrically charged gas through a small nozzle to hit the workpiece at high velocity and pressure, eroding and melting a cutting path through the material. Essentially, compressed air or inert gasses like argon or nitrogen are forced through a small nozzle at high speeds. The combination of gas, high speed, pressure, and an external electric charge form the plasma, which is an electrically conductive ionized gas that can reach temperatures of up to 20,000 °C. Similar to a laser cutter, a plasma cutter is a thermal cutting method where the material is melted in order to cut through it. Steel, stainless steel, aluminum, brass, and copper are among the common materials cut with a plasma torch. Only conductive metals can be used with plasma torches because the workpiece completes the electrical circuit. Plasma cutters are widely used in fabrication shops, auto repair and restoration, and industrial construction.

Cutting surface

The cutting surface of laser cutters is without burrs, smooth, and has good cut quality. Plasma cutters, on the other hand, are known to have poor perpendicularity. They create cuts with more cutting slag that needs to be removed by grinding, thus increasing the labor cost. Overall, laser cutters have a better surface finish, making laser cutting ideal for intricate designs.

Laser cutters produce cuts with very narrow slot widths of approximately ±0.15 mm and high precision of 0.01 mm or less. Plasma cutters, on the other hand, have a larger slot width (larger than 3.8 mm) and a precision of about 0.5-1 mm. The precision of both these cutters is influenced by the thickness of the material that is being cut. More power will be required for thicker materials, which leads to larger nozzles and a higher electrical current and results in a larger cut width.